It’s a green cure for what ails our nation’s crumbling infrastructure: lightweight but heavy-duty structural beams made out of recycled plastic.

Is plastic the new steel? Axion International of New Providence, N.J., is using technology developed at Rutgers University to build I-beams from recycled plastics. The beams today are used to build small bridges, a potentially big opportunity. (Studies say 80,000 such structures in the U.S. are nearly obsolete.) Axion says its beams are cost-competitive, and unlike rival materials, they won’t rust, corrode — or be eaten by termites.

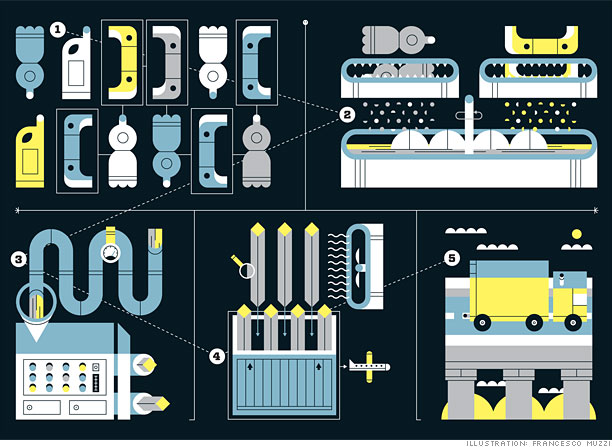

1. Raw material

Bales of No. 2 plastic (detergent bottles, milk jugs, and the like) and industrial-grade plastics (scrapped car bumpers) arrive at the Axion plant for processing.

2. Let it snow

The plastics are put through a heavy-duty shredder and turned into snowflakes. Axion says each pound of an I-beam uses the equivalent of eight plastic bottles.

3. Secret sauce

The flakes are combined with fiberglass and fed into a manifold, where the mix is heated but not melted — and readied for molding into I-beams.

4. Extrusion

The softened polymer is extruded — or forced into molds of different sizes based on the specifications of the project — pressed into shape, and then cooled.

5. Plastic at work

The beams are assembled into lightweight but strong bridges. How sturdy? An Axion structure at North Carolina’s Fort Bragg supports tanks weighing 60 tons.

Source : money.cnn.com