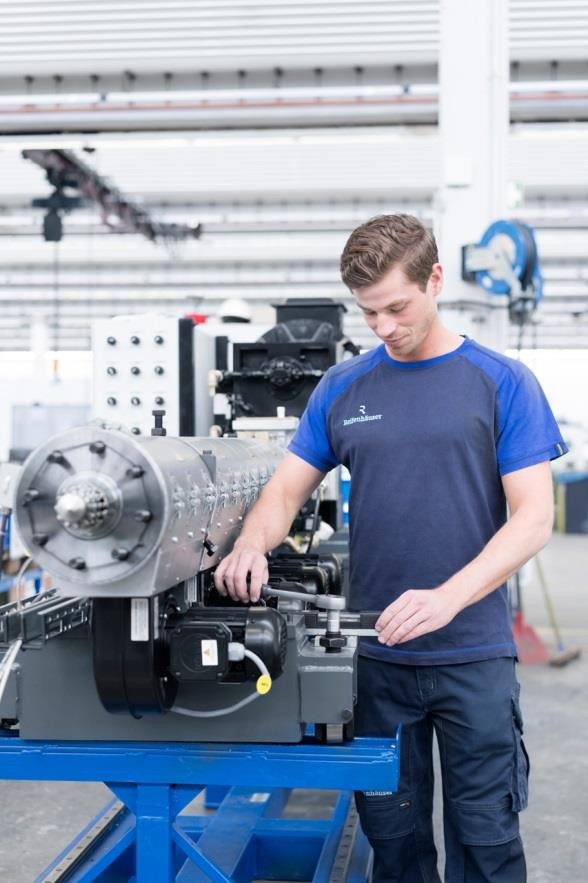

Troisdorf, July 1, 2019 | Buy new or retrofit? Users in plastics extrusion are faced with this question when looking at the performance of their lines in terms of energy consumption or the use of alternative raw materials. And this is where Reifenhäuser comes in with its latest business unit: Reifenhäuser Extrusion Systems (RES), which was founded in May, specializes in components for demanding applications in extrusion, and – as ever – focuses on sustainability. The Reifenhäuser Group’s new business unit covers the following product areas: screws and barrels, extruders, flat dies, and extrusion tools. In setting up this new business unit, the Troisdorf- based family company has brought all the expertise of the Reiloy, Extruders, Enka Tecnica and Extrusion Dies divisions under a single roof.

Modernization and conversion instead of new purchases

RES will be presenting its products at K 2019 under the slogan “Replace”. “Why exchange your extruder or die for a new one if it’s cheaper not to?“ asked Philip Neumann, Sales Director at Reifenhäuser. “We offer fully customized yet affordable solutions to update existing lines to the latest state of the art.” RES provides value with improved product quality, a worldwide sales and service network, extensive engineering know-how, and expertise in technical processes. All this from the point of view of economic efficiency and sustainability, allowing for example for more energy efficiency in production or for a larger share of workable recyclates. All products are offered at delivery times in line with the market and will be presented to the general public for the first time at K 2019.

Reifenhäuser single components increase the value of existing lines What’s new is that Reifenhäuser is selling its valuable extrusion components independently of a extrusion line. As of now, the product portfolio will be available on the free market to all customers – both processors and plant construction firms – and not only to Reifenhäuser’s affiliates, as previously.

Reifenhäuser expertise delivers longer product life cycles

“We can do extrusion,” commented Philip Neumann. “As the Extrusioneers, we are the perfect partner for optimizing existing extruders and thereby significantly increasing their performance. The customer receives an individually designed, premium-quality solution within a delivery period in line with the market and at an attractive price.”

Discover our excellent technologies and expertise for yourself at K 2019, the industry’s leading trade fair, in Düsseldorf from October 16 to 23. Enjoy finding out how we showcase our solutions, and get all the details first hand at our trade fair in hall 11, B22 (srews&barrels, extruders) and hall 1, E40 (flat dies).

About Reifenhäuser RES

Reifenhäuser Extrusion Systems (RES) covers the following product areas: screws and barrels, extruders, flat and round dies, and film die-heads. RES brings the Reiloy, Extruders, Enca Tecnica, and Extrusion Dies divisions with all their engineering, product, and process expertise together under a single roof. What’s new is that the components are now produced for the free market, not just for affiliates, as previously.

About the Reifenhäuser Group

Reifenhäuser Extrusion Systems (RES) is a member of the Reifenhäuser Group, the leading provider of innovative technologies and components for plastics extrusion. Founded in 1911, the company delivers advanced solutions to customers around the world through its highly specialized business units. With its technologies and the know-how of its 1,500 employees, Reifenhäuser has the world’s largest network of expertise in plastics extrusion technologies. The CEO of the Group is Bernd Reifenhäuser.

Reifenhäuser GmbH & Co. KG Maschinenfabrik

Spicher Strasse 46, 53844 Troisdorf, Germany

T +49 (0)2241 23510-0, F +49 (0)2241 23510-790

www.reifenhauser.com