Lancaster-based Connect 2 Cleanrooms has assisted Tex Plastics increase its manufacturing capability offering with a cleanroom production.

Tex Plastics’ aim to develop higher performing, lower cost solutions for its clients, has now been complemented with a class 7/8 clean room system that includes automated clean-air HEPA-lite.

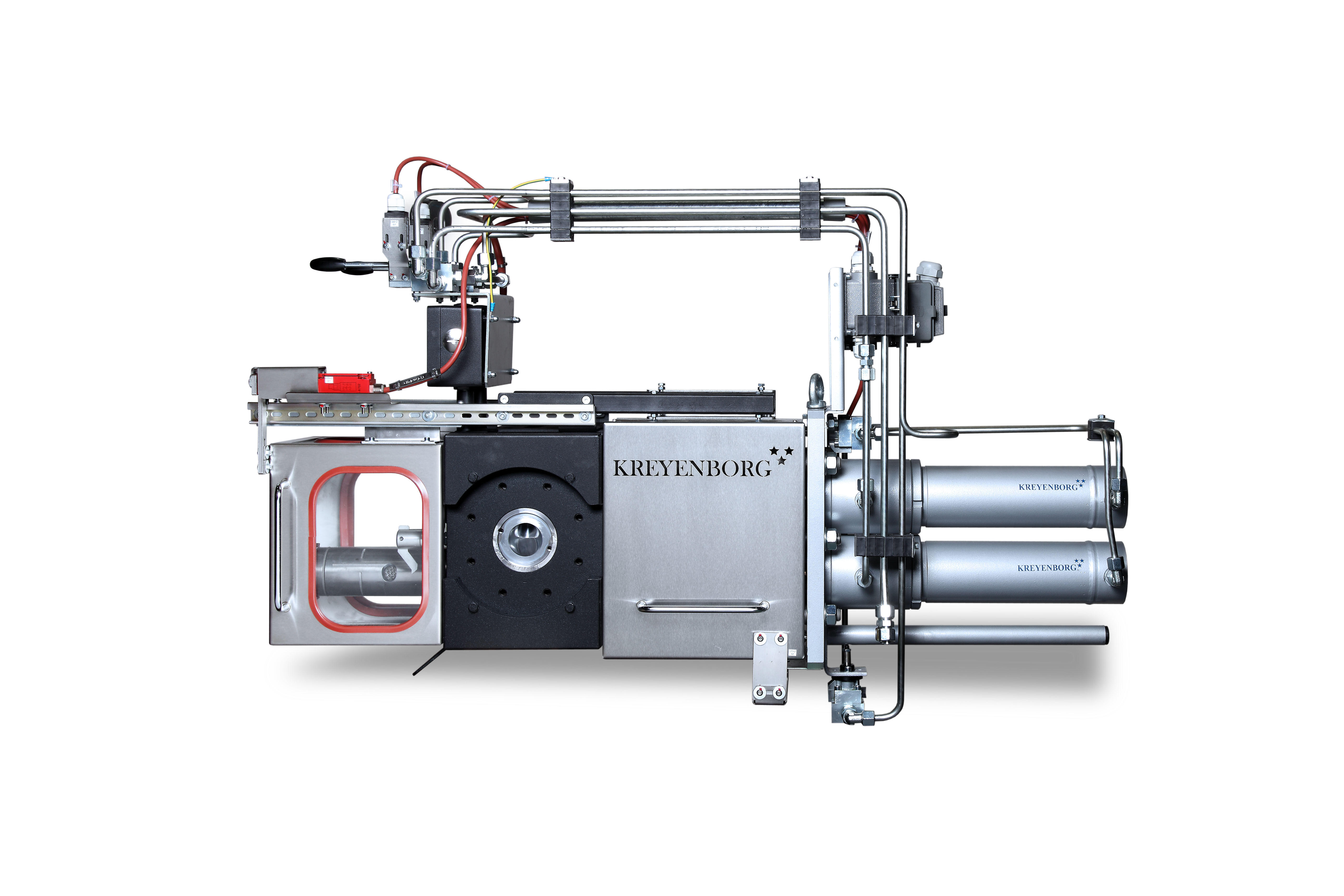

The Connect 2 Cleanrooms canopy unit aims to ensure that clean air is supplied at critical points of production and reduces contamination by significantly limiting the areas of machinery that are exposed to the external environment during tooling changes.

This limits downtime for cleaning, reduces risk of contamination and increases productivity – which is what Tex Plastics is aiming to achieve.

There are four zones inside Tex Plastics’ clean room separated by partitions; two for Arburg injection moulding machines , a packing area, and a good transfer area.

The system was developed to solve many issues and increased risks of contamination that occur when considering the injection moulding processes that Tex Plastics is aiming to eliminate.

The tool face of the machine is often the most exposed area of the production line and this is the area which often requires the supply of controlled air.

A way of achieving this, is to enclose the full machine in a cleanroom, although this also brings inevitable challenges of tool changes.

By enclosing the machine, mould and crane, a large environment is created and this leads to a vast amount of air being unnecessarily processed.

Unnecessarily processed air can contribute negatively to the companies attempts to reduce carbon emissions.

A more cost effective option could be to create a modular cleanroom on castors. While this is a low-cost solution for many, Tex Plastics concluded that it creates unacceptable downtime as machinery requires an extensive full clean down following exposer to the external manufacturing environment.

Tex Plastics supplied 3D models of their machines allowing Connect 2 Cleanrooms to maximise on floor space when designing its cleanroom and ensure a seamless installation programme with minimal disruption to Tex Plastic’s production team.

The cleanroom is now fully operational, complimenting an already comprehensive “concept to completion” project solution for all conventional, white room and cleanroom thermoplastic requirements.

Website: www.engineeringcapacity.com