Ghent, Belgium – Milliken focuses on improving all-round mechanical performance and aesthetics of lightweight polypropylene (PP) and polyurethane (PU) parts to meet the high requirements of the automotive industry at the forthcoming 2016 VDI Plastics in Automotive Engineering Conference in Mannheim, Germany.

At Booth 19, Milliken will showcase additives from its Milliguard® range valued for advancing the performance of PU and TPU applications without contributing to VOC emissions. Milliken’s polymeric technologies are 100% reactive into the PU foam, elastomer or coating. Integrated within the final PU article during manufacturing, they avoid migration and loss of properties over time, and help to address the major issues of degradation and discoloration of PU articles due to light and heat sensitivity.

For the automotive industry, Milliken’s unique antioxidant Milliguard AOX-1 addresses more stringent environmental, health and safety requirements, including indoor air quality standards. Test results achieved by Milliken consistently show Milliguard AOX antioxidant significantly reduces VOC content and dramatically minimizes FOG content emission associated with anti-oxidant compared to industry standards. Milliguard UVX improves UV performance and VDA 278 compliance for highly demanding PU and TPU applications, including elastomers, coatings and stay-white PU foam parts.

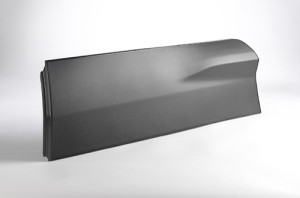

Visitors can also look forward to the weight-reduction benefits and more offered by Hyperform® HPR-803i reinforcing agent.

The synthetic reinforcing agent, used alone or with talc, allows automotive designers to create high-performance PP parts that are up to 15% lighter without compromising performance. Added at a lower addition rate than mineral fillers, Hyperform HPR-803i reinforcing agent ensures lower density PP compounds which maintain their mechanical performance even after multiple recycling and compounding operations. Hyperform HPR-803i reinforcing agent also enables a reduction in color pigment usage and improves scratch resistance of a finished part.

Designers are invited to explore the innovative abilities of Hyperform HPN nucleating additives for achieving stronger, thinner and lighter PP parts with stable dimensions, even in the most demanding circumstances. Animations of a PP bumper produced using Hyperform HPN 20E additive will demonstrate how the outstanding balance of stiffness and impact strength contributes to improving all-round mechanical performance in all temperature conditions, and creates room for material downgauging.

“By combining possibilities for weight reduction with high-performance properties and features, Milliken’s innovations are at the forefront of supporting the automotive industry in improving sustainability and its efforts to lower vehicle emissions,” comments Philippe Scheerlinck, New Business Development Manager EMEA, Milliken.

Website: www.millikenchemical.com