Processing Technologies International (PTi), a manufacturer of sheet extrusion machinery based in the US, has completed the installation of

Processing Technologies International (PTi), a manufacturer of sheet extrusion machinery based in the US, has completed the installation of

its “dryer-less” twin-screw sheet extrusion production system at its headquarters in Aurora, the company announced on September 17.

A demonstration system was on display during a plant tour in conjunction with the recently concluded 20th annual SEP Thermoforming Conference. PTi said it has invested US$3 million to install the unit.

“The launch of this unique technology is of major significance for our customers who now have an eco-conscious manufacturing solution which delivers major energy savings and cost reduction,” said Dennis Paradise, PTi’s Senior Vice President of Sales and Marketing. “Moreover, it is the only full-scale ‘dryer-less’ twin-screw sheet extrusion demonstration system available for trials in North America.”

PTi said sheet manufacturers can request to test their own virgin or recycled materials with the demonstration line, which is in production-scale, while customers are welcomed to produce samples sufficient for test marketing.

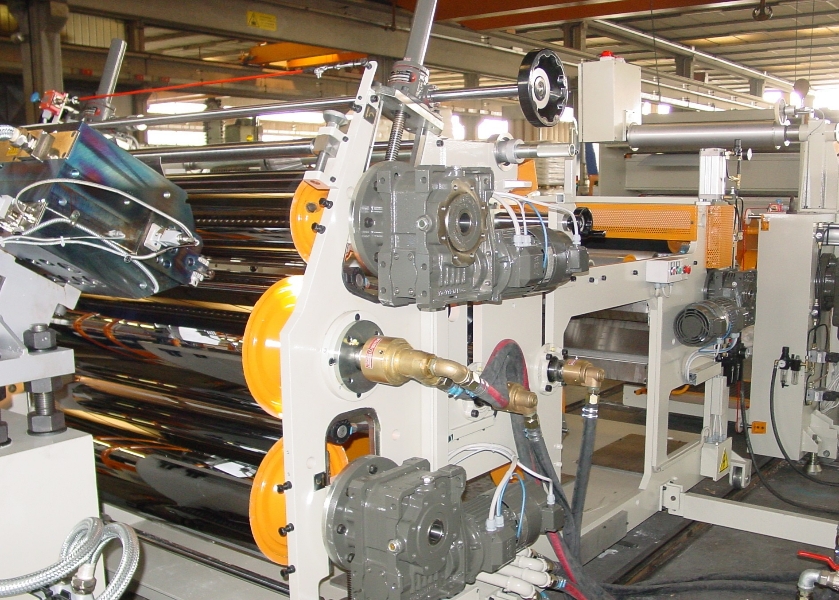

PTi’s “dryer-less” twin-screw sheet extrusion production system comprises a single atmospheric and dual high vacuum, vent system with a co-rotating twin-screw extruder. The structure removes moisture and other volatiles during the extrusion process. The re-crystallization process for recycled PET is also skipped. PTi stated that 30-35% of energy is saved comparing to conventional extrusion method.

The processing rate of the unit could exceed 2000 lb per hour (900kg/hr). It is able to run a variety of resins including recycled and industrial PET/PLA. The patented High-Vacuum Twin-Screw Extruder (HVTSE) technology supplied by Italy’s Luigi Bandera allows the materials being processed eliminate the drying and crystallizing procedure.

Source : www.adsalecprj.com