At Hannover Messe 2015, igus announced that a new 3D printing service is now available for producing prototypes with its tribo-filament.

“Our customers can contact us with their 3D data and get their parts quickly and easily printed by us,” said Tom Krause, Product Manager at igus iglidur tribo-filament. “This is what we have been occasionally carrying out in recent months and now wants to offer this service to all our customers.”

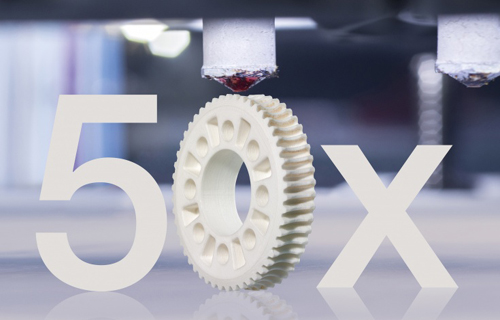

Igus’ iglidur tribo-filament is reportedly 50 times more abrasion resistant than conventional 3D printing materials and delivers more unusual geometries quickly and easily.

Customers can upload their data on igus website, as well as the components ordered. The prices are also determined automatically online, and similar to the indication of the delivery time, the price also depends on the complexity and the structure of the component.

“It is also possible for us to print components from two different plastics,” said Mr Krause. “That means it can print either very complicated components in which the support material dissolves, or the component is printed from a normal ABS and only the sliding surfaces are made of our abrasion-resistant iglidur I180-PF.”

In the future, complex shapes can be printed from more iglidur standard materials to offer users more creative freedom in their designs, according to the company.

igus offered, as a first step, components such as worm gears from this first low wear tribo-material at Hannover Messe 2015, which was held from April 25-29 in Hannover, Germany.

Website: www.adsalecprj.com