Grafenberg, 11/06/2014. From the start of the new financial year on 1 July, 2014, the RAMPF Group’s five core companies will be operating under new names, thus reflecting the much broader service portfolio and growing internationalization of the Group.

Nomen est omen – From 1 July, 2014, the names will spell out the core areas of expertise offered by the international RAMPF Group:

EPUCRET Mineralgusstechnik is becoming RAMPF Machine Systems

RAMPF Dosiertechnik is becoming RAMPF Production Systems

RAMPF Ecosystems is becoming RAMPF Eco Solutions

RAMPF Giessharze is becoming RAMPF Polymer Solutions

RAMPF Tooling is becoming RAMPF Tooling Solutions

“The RAMPF Group stands for engineering and chemical solutions. The companies in the Group harness the diverse range of innovative potential that comes from combining engineering and chemical solutions. These areas of expertise are covered by the terms systems and solutions,” explains Michael Rampf, CEO of RAMPF Holding. “The new company names reflect the much broader portfolios that our companies have built up over the years. The English terminology better portrays RAMPF’s global presence on the world markets as a solutions-oriented, full-service provider.”

As well as strengthening our position on the market, this rebranding is meant to consolidate the sense of cohesion throughout the Group and encourage closer collaboration across the operating units. “The high levels of skills and thirst for innovation at RAMPF are quite unrivalled and place us far ahead of the competition,” says Matthias Rampf, CEO of RAMPF Holding. “We want to start making even better use of this potential by collaborating more intensely across countries, companies, and departments.”

RAMPF – innovative solutions from a single source

The managing directors of the five core companies of the RAMPF Group explain the reasons behind the rebranding and why their respective companies are ideally positioned for future growth:

Dr.-Ing. Utz-Volker Jackisch and Martin Neumann, Managing Directors of RAMPF Machine Systems: ”Over the past 18 years, our company has moved from being purely a mineral casting specialist to being a development partner and systems supplier for complete machine bed solutions and machine systems. This was necessary because customer demands went beyond just machine beds – they want complete machine systems. This gives rise to new products and services such as EPUTRONIC, EPUGRIND, and EPUDESIGN. There is no such thing as a one-size-fits-all machine bed material. Market requirements make it necessary to add alternative materials to our product portfolio, and we have met this demand with EPUMENT, EPUDUR, EPUSTONE, EPUFIBER, and EPUFOAM.“

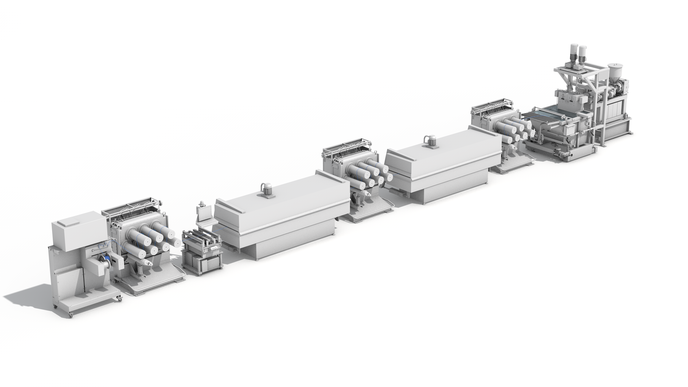

Bernd Faller, Managing Director of RAMPF Production Systems: “Our previous name limited our production and solutions portfolio to dispensing technology. ‘Production Systems’ clearly shows that we provide complete system solutions for our customers’ production operations. Our core competence of mixing and dispensing technology is joined by a broad range of automation and conveyor systems for internal logistics, additional assembly and joining technology, as well as logistic and quality assurance solutions. The integration of testing and measuring technology into production facilities to safeguard production processes will increasingly play a part in our customer-specific solutions.“

Matthias Rampf, Managing Director of RAMPF Eco Solutions: ”The core competence of RAMPF Eco Solutions is the manufacture of high-quality alternative polyols from PU waste materials. Using innovative chemical solutions, the waste production materials from PU manufacturers are developed into polyols tailored precisely to their requirements. We have also developed chemical processes that enable us to use PET, PA, PC, and renewable resources such as vegetable oils as raw materials for producing high-tech alternative polyols. Our expertise also flows into the planning and construction of customer-specific PU recycling plants and facilities for the manufacturing of alternative polyols using PET and PA. This enables our customers to produce high-quality alternative polyols cost-effectively and on site.“

Dr. Klaus Schamel, Managing Director of RAMPF Polymer Solutions: ”By adopting the name ‘Polymer Solutions’, we are showing our commitment to developing and producing high-quality casting resins that are tailored specifically to our customers’ needs, and to doing so more effectively than ever before. In the past few years, we have significantly boosted our expertise in both product development for new applications and in application engineering. ‘Solutions’ also means that we support our customers in both product development and product application. A large team of technical field representatives, application technicians, and product developers helps our customers to optimize their processes and solve their problems.“

Heinz Horbanski, Managing Director of RAMPF Tooling Solutions: ”’Solutions’ describes the wide range of services we provide in addition to manufacturing liquid, paste, Close Contour, and block materials for model, mold, and tool engineering. We have significantly expanded our expertise in consulting and application technology. Our customers have the opportunity to familiarize themselves with our products and solutions on a practical level, and we provide comprehensive advice and support for product applications and construction methods. With Close Contour Casting Services, we provide Close Contour Castings as full castings, shell castings, blocks, and wheel rim blanks that are specially designed and cast to the customer’s specific requirements.“

RAMPF Holding GmbH & Co. KG

Albstrasse 37

D-72661 Grafenberg

T +49.71 23.93 42-1045

F +49.71 23.93 42-2045

E [email protected]

www.rampf-gruppe.de