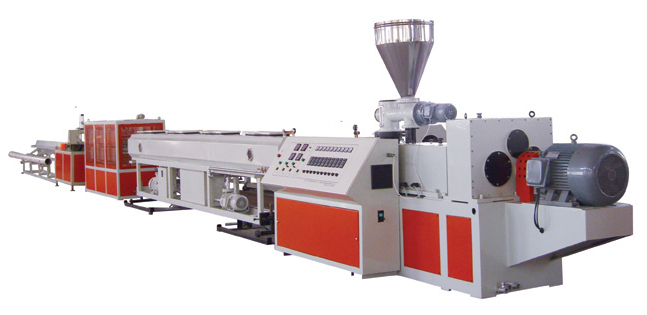

Since 1958 AMUT, headquartered in Novara – Italy, is a global leader in the plastics extrusion field and manufactures different lines configurations to extrude pipes, offering solutions for several materials and diameters. The range of production includes: PVC pipe lines with diameter of 16-1200 mm for rigid pipes and 8-63 mm for flexible ones, PE pipe lines (mono and multilayer) with diameter of 16-1600 mm and special pipes (multilayer) such as PE-X, PA (fuel pipe), PP with glass fiber reinforced inner layer (hot water), flexible PVC braided/reinforced hoses, irrigation, foam core, corrugated, bi-oriented and automotive pipes.

Focused on the particular needs of its customers, AMUT mainly develops tailored lines and special equipment. For instance, AMUT delivered in Vietnam an extrusion line for the production of PE100 pipes with an external diameter of 1000 mm: a new compact extrusion die and an extruder capable to reach an hourly capacity of 1200 kg have been specifically designed and manufactured for this purpose. The die is provided with 16-spiral distributors to guarantee a perfect wall thickness uniformity on the whole pipe, while the extruder is based on bimetallic barrel and wear-proof coated screw.

For the automotive industry, AMUT proposes to the market lines to produce multi-layer PA pipes (up to 5 layers) which are largely used to convey fuels or hydraulic oils. These PA pipes are performing good flexibility, reduced water absorption and high resistance to low temperatures, humidity, cracking and abrasion. Though a continuous thickness control and diameter adjusting system, AMUT lines always assure top quality pipes, even changing frequently product features and dimensions, at constant production working conditions.

For the automotive industry, AMUT proposes to the market lines to produce multi-layer PA pipes (up to 5 layers) which are largely used to convey fuels or hydraulic oils. These PA pipes are performing good flexibility, reduced water absorption and high resistance to low temperatures, humidity, cracking and abrasion. Though a continuous thickness control and diameter adjusting system, AMUT lines always assure top quality pipes, even changing frequently product features and dimensions, at constant production working conditions.

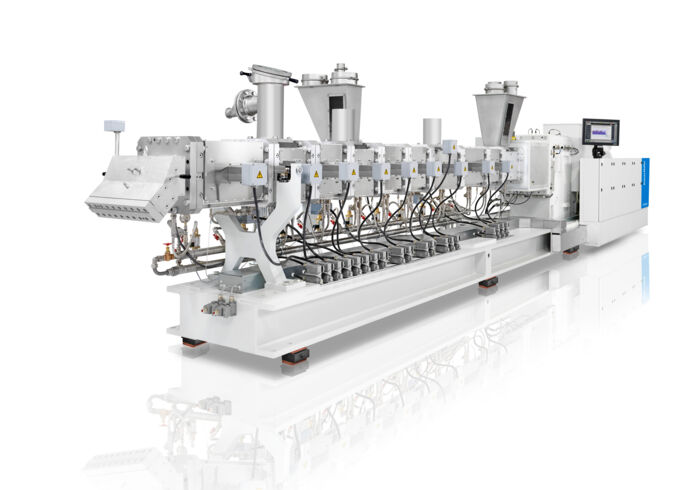

Moreover, AMUT extrusion lines are supplied with gravimetric dosing units to keep constant the layers thickness and to control the size and weight of the pipes. Plasticizing units, barrels and screws, are all made of special alloys (to ensure a good resistance to abrasion and corrosion) and their particular geometries are essential to get high production rates and homogeneous quality of the melt, at low energy consumptions.

Moreover, AMUT extrusion lines are supplied with gravimetric dosing units to keep constant the layers thickness and to control the size and weight of the pipes. Plasticizing units, barrels and screws, are all made of special alloys (to ensure a good resistance to abrasion and corrosion) and their particular geometries are essential to get high production rates and homogeneous quality of the melt, at low energy consumptions.

The limited friction of the extruded material in the sizers allows to control tension acting on the pipe, to achieve high extrusion speed (such as 60 – 70 m/min in case of 5 layers pipe extrusion).

AMUT spa – Clever solutions for plastics

Via Cameri,16-28100 Novara, Italy

Phone +39 0321 664 949

Fax +39 0321 474 200

mailto [email protected]

www.amut.it