KraussMaffei Berstorff has recently developed a cost-effective production process for multi-layer polyvinyl chloride (PVC) floor coverings, also referred to as Luxury Vinyl Tiles (LVT).

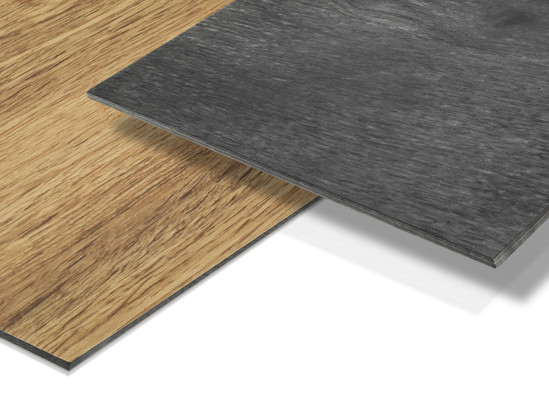

LVT flooring is composed of a highly filled core layer – usually provided with an integrated glass mat – plus decorative film and a wear protection layer. While the glass mat gives strength and dimensional stability, the core layer provides flatness of the floor covering and impact sound insulation.

For this purpose, the PVC sheet material is filled up to 60 to 70% with mineral additives to obtain thick sheeting of high density and weight. The decorative film is laminated to the thick sheeting to produce the desired design and the product is rounded off by wear protection layers of different thickness depending on the future application.

Similar to roofing sheets, the three-layer floor covering core is produced on two twin-screw extruders and two smoothing calendars. The first extruder, used for plasticizing and homogenizing a PVC compound, is equipped with a side feeder to incorporate a high mineral filler share and additional additives.

The material leaving the extruder is applied to the glass mat on the first downstream smoothing calendar. The composite obtained is then guided through the second smoothing calendar to apply the PVC compound – previously processed on the second extruder – to the other side of the glass mat.

KraussMaffei Berstorff said this method offers the decisive benefit that processing, compounding and tile production are carried out in-line, which is of fundamental importance for heat-sensitive PVC in particular.

Downstream from the second smoothing calendar, the three-layer core material is provided with the decorative film and the wear protection layer. The five-layer composite then passes through an embossing station as well as a temperature control section to ensure dimensional stability before being cut to size.

According to Hilmar Heithorst, Division Manager for Sheet and Foam Extrusion Lines at KraussMaffei Berstorff, LVT is poised for strong growth in Europe and North America due to the benefits of unlimited appealing design options that range from natural wood to stone optics of any color.

In addition, thanks to their moisture resistance, LVT can also be used in wet rooms such as kitchens or bathrooms. They provide good impact sound insulation. Feeling naturally warm, they are also suitable for use with underfloor heating.