ExxonMobil Chemical will be showcasing a wide array of solutions at the CHINAPLAS 2014. One of the highlights will be the specialty elastomers Santoprene thermoplastic vulcanizates (TPVs) for automotive application.

According to the company, thanks to the combination of the characteristics of vulcanized rubber and the processing ease of thermoplastics, Santoprene TPVs have proven to be dependable polymers for flexible engineered parts that require high performance and consistent durability. In automotive application, they are helping to build high performance and lighter weight vehicles at lower system costs.

When compared with materials such as thermoset rubber (TSR) or ethylene propylene diene monomer (EPDM) rubber, Santoprene TPVs, which have lower density, deliver enhanced performance and the potential for reduced system costs, and the possibility of sustainability benefits, including reduced weight, more sustainable manufacturing and recycling, for automotive and demanding industrial applications.

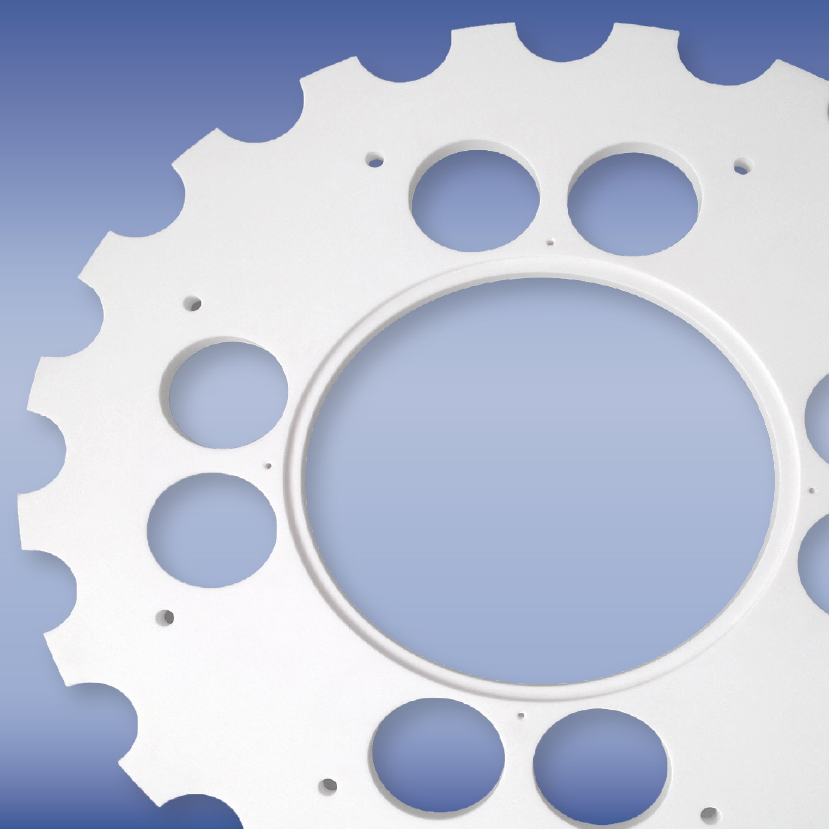

As said, Santoprene TPV can deliver 29% weight savings for glass run channel (GRC) weatherseal systems compared to EPDM rubber and 25 to 45% weight savings for clean air ducts versus thermoset rubber compounds. Moreover, it contributes to overall waste reduction in the manufacturing process, as scrap produced during processing can be recycled.

Other sustainability opportunities of Santoprene TPVs in manufacturing include:

• Do not require heat curing – cutting manufacturing energy costs up to 50% compared to EPDM rubber

• Due to integrated manufacturing, such as multi-K injection molding, chemical usage is reduced because spray coatings and adhesive application are not needed

• Manufacturing space is reduced because typical TPV extrusion lines only need one-third of the space used by comparable EPDM lines

Meanwhile, at the fairground, ExxonMobil and its partners will also be presenting:

• Durable, high-quality beverage cups – Milacron will demonstrate how the combination of its Elektron 350T technology and Vistamaxx PBE produces high-quality beverage cups with excellent impact performance

• High-performance, 5-layer cast power pre-stretch films – XinLe HuaBao will demonstrate how it has used Exceed and Enable mPE resins and Vistamaxx PBE with its 5-layer coextrusion technology to produce high-performance cast power pre-stretch machine wrap packaging films

• High performance masterbatch – Xiner will showcase how it improves masterbatch performance and lowers costs with the addition of Vistamaxx PBE

• Simplifying foaming sheet manufacture – By adding Vistamaxx 6102 PBE to its new patented chemical foaming agent, Polyfil Corporation was able to simplify the manufacture of lightweight, flexible, and strong foamed PP sheet products