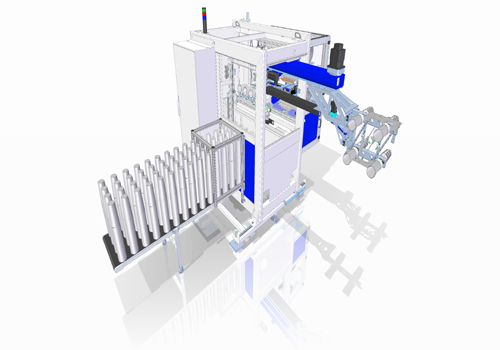

Palram Israel Ltd, a manufacturer of thermoplastic semi-finished products, polycarbonate (PC) and polyvinyl chloride (PVC) sheets, has recently installed a KraussMaffei Berstorff co-extrusion line for production of multi-layer PVC sheets with a finished width of 2,030mm for a wide range of applications.

The system is equipped with a KMD 133-32/PL 32D twin-screw extruder and used by Palram in conjunction with a KMD 75-26/PL co-extruder to produce multi-layer sheets using the co-extrusion method.

“A critical criterion for any investment decision we make is flexibility, because we want this system to work with varying formulations and manufacture a variety of final products,” explains Avinoam Gershoni, Group Technical Purchasing Manager of Palram.

“Thanks to the co-extrusion technology supplied by KraussMaffei Berstorff, we can respond very quickly and flexibly to the wishes of our customers. For example, we manufacture free-foamed and co-extruded multilayer sheets as well as transparent PVC sheets,” he adds. “The ability to manufacture such a wide range of products enables us to stay competitive.”

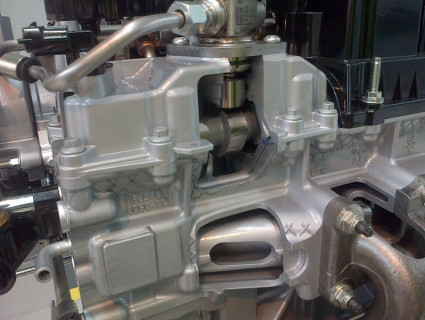

“The centerpiece of our 32D twin-screw extruder, the screw, has a specially adapted geometry for sheet extrusion which ensures exact temperature control,” explains Peter Oswald, Head of Product Management at KraussMaffei Berstorff. It results in good melt homogeneity which ensures the product quality and high output levels, in this case, up to 1200kg/h.