At the K 2013 trade fair in Düsseldorf, WITTMANN is presenting the latest model from its line of FLOWCON flow regulators: the FLOWCON plus with proportionally controlled stepper motor and wear-free flow meter. By replacing the solenoid valves of the previous model, this enables proportional control of the valves, which allows for a significant improvement in temperature control.

The valves of the FLOWCON plus can be used both as simple control valves with flow monitoring and in combination with a temperature probe to regulate mold temperature.Process data such as flow and temperature values can be entered either on the touch screen of the teach box or directly on the control panel screen of the processing unit, because it is connected to the flow regulator via an interface.

The key advantage of this type of flow regulator over a manually adjustable one is that it permits continuous electronic monitoring of the preset flow and temperature values. All data are logged and can be automatically adjusted proportionally via control valves. Already proven in service many times over, the WITTMANN fine regulating valve of the 301 Series performs the flow regulation function here.

Generously dimensioned channels in the casing blocks guarantee the lowest possible pressure loss and high flow rates.Additional options for the FLOWCON plus are currently under development: the ability to connect directly to the fully electric EcoPower injection molding machine from WITTMANN BATTENFELD, for example, as well as the ability to blow mold channels out with compressed air and the ability to switch from cold water regulation to the operation of a temperature control device.

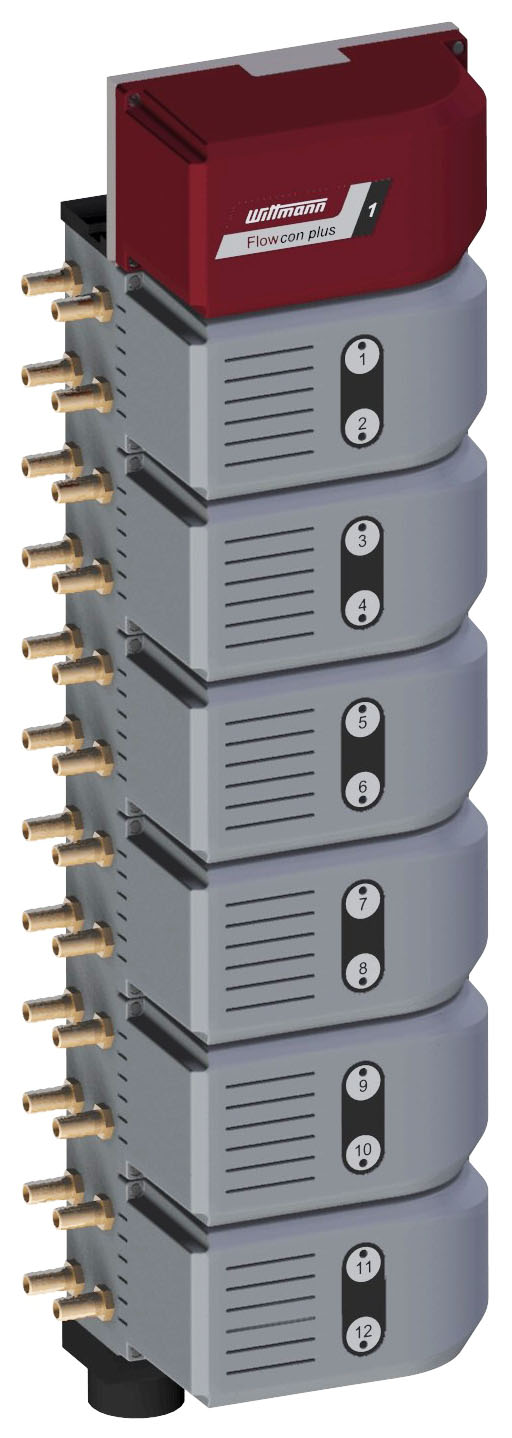

The maximum equipment configuration of the FLOWCON plus features 4 × 12 cooling circuits, which are connected to one another via a data cable.