Sophisticated sorting solutions for a closed loop material cycle

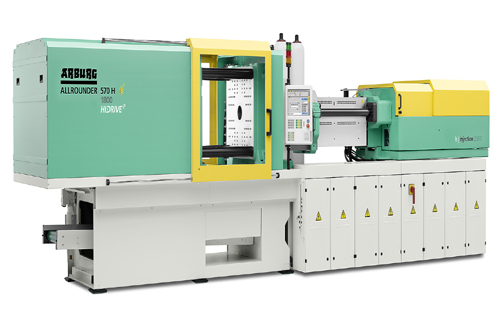

Schönberg, August 2013-At PETpoint 2013 in Munich, 16 to 20 September 2013, S+S Separation and Sorting Technology GmbH, hall B3, stand 302, are presenting an extensive product portfolio: Sorting systems for the recycling of used PET packaging, and inductive metal separators that for example are used in the injection-moulding of PET preforms or caps. The trade fair focus is the FLAKE PURIFIER system for the sorting of PET flakes.

The FLAKE PURIFIER was shown for the first time at PETpoint 2009, and since then the sys-tem has found widespread use by many PET recyclers worldwide. Based on a modular concept, up to three sensors for contaminant detection can be combined in the system. Apart from sen-sors for metal and colour separation, the FLAKE PURIFIER system also features a high-performance module for the detection of contaminant materials, including different types of plas-tics.

For example, PVC content or bioplastics such as PLA, which otherwise would mean con-siderably reduced quality of recycled material or can even render high-quality recycling impos-sible, can be removed from PET flakes. The intelligent combination with camera sensors makes it possible to identify incorrect colours even with very small colour shade differences. Metal par-ticles are detected by inductive sensors. An air-blast unit matched to the application ensures the reliable and efficient (little loss of good material, reduced compressed-air requirements) separa-tion of unwanted particles.

The FLAKE PURIFIER features a compact modular design and high energy efficiency, which does not require separate cooling. When the sorting tasks change, systems with only one sensor at any time can be upgraded to higher-performance systems. Altogether the FLAKE PURIFIER is a cost-efficient solution that guarantees high-quality, food-grade recycled raw materials.

Says Michael Perl, manager of the sorting business unit at S+S, on the S+S product portfolio on show at PETpoint 2013: “Apart from the primary focus on PET recycling we are also presenting systems for quality assurance in PET production. It is a particular strength of S+S that we can provide comprehensive and technically sophisticated inspection and separation solutions both for customers in the fields of plastics production and processing, as well as for plastics recyclers.”

For making new bottles from used PET bottles, the recycled PET must be of food-grade quality. The S+S FLAKE PURIFIER separates contaminants – metals, particles of wrong colour, un-wanted types of plastics – from PET flakes.