ALPHARETTA, Ga., June 13, 2013 – Implantable catheter ports from Plan 1 Health S.r.l, Amaro, Italy, a leading designer and manufacturer of implantable dental and infusion systems, are made of Eviva® polysulfone (PSU) resin from Solvay Specialty Polymers for biocompatibility, dimensional stability, and MRI compatibility. Eviva® PSU resin is part of Solvay’s Solviva® Biomaterials line offered for use in implantable medical devices.

Plan 1 Health’s Healthport® catheter port system is versatile and highly reliable for delivery of drugs, antibiotics, and nutrient therapy solutions. The Healthport® Plastics Low Profile (PLP) model is lightweight and cost-effective, and it features a low-profile PSU housing that is suitable for all patients. A titanium inner chamber avoids damage induced by the needle tip and avoids interactions between Eviva® PSU and the drug. A large self-sealing septum facilitates location during skin palpation and reduces the risk of puncture concentration. A transparent polyurethane connector allows a rapid, safe, and reversible connection of the catheter.

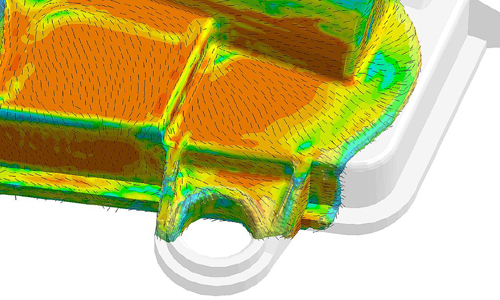

The catheter port is a multi-piece assembly consisting of an injection molded housing and ring component, both made of Eviva® PSU, and a titanium inner chamber. The PLP model is lighter and more cost-effective than previous all-titanium versions which require more expensive manufacturing techniques, according to Alessandro Rainis, product manager for Plan 1 Health. The titanium chamber is fixed between the two plastic components that are ultrasonically welded together.

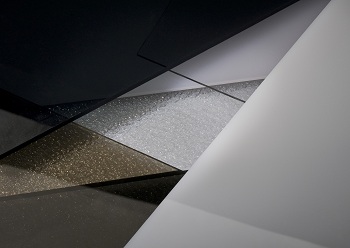

Eviva® PSU is a transparent polymer that offers toughness and strong biocompatibility. The material maintains its dimensional tolerance right out of the mold and requires no machining. It is a rigid thermoplastic that doesn’t absorb fluids and is artifact-free for effective MRI imaging.

“We’ve been very pleased to work with Plan 1 Health as they develop advanced approaches for implantable infusion systems,” said Shawn Shorrock, global healthcare market manager for Solvay Specialty Polymers. “The ongoing acceptance of Eviva® PSU has validated our approach to the implantable infusion market and we’re encouraged by the momentum we’ve generated.”

The manufacturing site for Eviva® PSU and other Solviva® Biomaterials in Alpharetta, Ga., is ISO 13485 registered and the relevant aspects of current Good Manufacturing Practices are also applied. Solvay’s Solviva® Biomaterial manufacturing processes are carefully validated and enhanced controls provide product traceability. In addition, all materials are tested in an ISO 17025 accredited lab. Based on biocompatibility testing, Eviva® PSU demonstrates no evidence of cytotoxicity, sensitization, irritation or acute systemic toxicity.

The catheter ports – sold to medical device distributors in Europe, Asia, and India – have earned the CE (Conformité Européenne) mark which demonstrates compliance with numerous EC directives, enabling the product to be sold throughout the Euro region. Plan 1 Health is also exploring the option of seeking 510(k) clearance from the U.S. Food & Drug Administration (FDA) and entering the U.S. market.

In addition to Eviva® PSU, Solvay’s Solviva® Biomaterials line includes Zeniva® polyetheretherketone (PEEK), which boasts a modulus very close to that of bone plus excellent toughness, biocompatibility and fatigue resistance; Proniva® self-reinforced polyphenylene (SRP), one of the world’s stiffest and strongest unreinforced thermoplastics, which offers exceptional biocompatibility and hardness; and Veriva® polyphenylsulfone (PPSU), which provides unsurpassed toughness combined with transparency and excellent biocompatibility.