Insertion and removal times are a crucial aspect of packaging and IML applications. For achieving the respective acceleration, drive torques are needed that are very close to the edge of feasibility. At speeds beyond 6 m/s, accelerations of more than 60 m/s² are absolutely common when using lightweight grippers.

The new WITTMANN all-wheel drive reaches these accelerations without difficulty.More and more, the market asks for systems that are able to handle higher payloads at constant dynamics. A straightforward solution might be a simple increase of the available motor performance.

This can indeed be achieved, but the approach has some serious disadvantages:

- Firstly, the mass inertia of a servo drive rises typically to the second – related to its performance. The bigger the motor, the higher the share of energy that has to drive the rotor. The outcomes are often overdimensioned and expensive driving packages. Unfortunately, these are all too often seen today in use with packaging and IML applications.

- The bevel of a toothed drive belt can only transmit a limited torque. Increasing torque, by necessity, means a broader toothed drive belt.

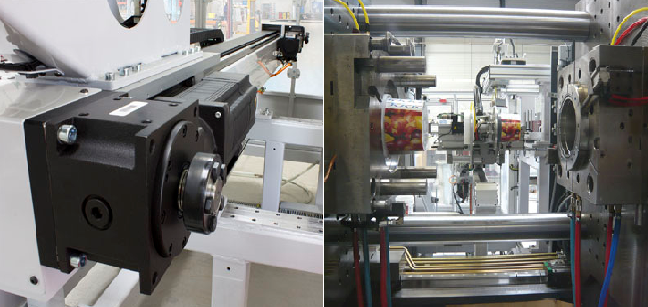

WITTMANN has now developed a superior solution for the highly dynamic W837 horizontal robots. Part of the answer is to use two smaller drives instead of one big motor.

WITTMANN product trials and research has shown that:

- Two motors, each of them of half the power, amount to more than the double dynamics of a single big motor.

- The mechanical power that is infed in the toothed drive belt now combines on two tooth wheels. The toothed drive belt and the proven basic construction of the robot remain unchanged, therefore enabling better service, and the extra drive effort can be kept within a limit.

The drive control and its sophisticated algorithms also ensure that the loads carried by each of the two drives are exactly the same.The new W837-2drive robot model will be introduced at the Competence Days of the WITTMANN Group in Kottingbrunn (April 24–25). The system will be shown in combination with an electric EcoPower 180/750 injection molding machine.

This new IML application will demonstrate the highly dynamic removal of lids from a fourfold mold, going far below a time limit of 0.5 seconds for the entire demolding time. The W837 robot differs from the standard model only through its double drive chain. This feature alone assures the highest flexibility and modularity when designing and commissioning such production systems.

More information :www.wittmann-group.com