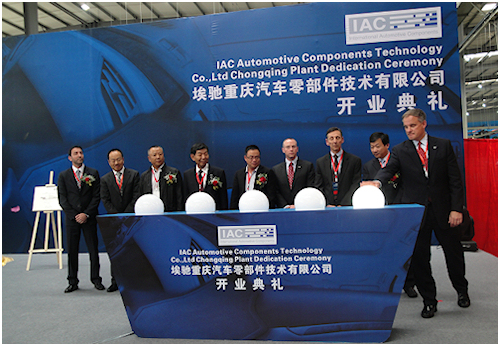

U.S. Tier One opens Chongqing auto skin facility

International Automotive Components (IAC, Luxembourg) has debuted its proprietary FastKast A-surface material manufacturing process for automotive skins in Asia. The new facility in Chongqing, China, supplies both the Ford Kuga and Ford Mondeo door panel and floor console assemblies, along with instrument panels, cockpits modules, finish trim panels and ducts for the Ford Mondeo. Additionally, IAC Chongqing supplies door panel assemblies, glove boxes and instrument panels for the Volvo S80L and will begin manufacturing instrument panel trim components for a new Suzuki model later this year.

The 10,400-sq-m Chongqing facility is a greenfield operation and employs approximately 275 personnel. It will consolidate an exist facility in the city, growing the total number of IAC manufacturing facilities in Asia to 17, supported by six technical and engineering centers. IAC’s presence in the Asia-Pacific region has expanded to include design and technical facilities and joint ventures in key markets including China, Korea, Japan, Malaysia and Thailand.

The FastKast employs thermoplastic polyolefins and polyvinyl chloride as skin materials, which reportedly enhance product quality, and improve tactile feel and aesthetics on instrument panels and other interior trim components. Late last year, FastKast debuted in support of Ford business at IAC’s manufacturing site in Bals, Romania.While details of the FastKast process itself are sketchy, an equipment list for the Chongqing facility indicates two machines delivered from IAC EU likely to be involved with the proces: a “slush machine” and a slush “Exchange Powder System.” An oven used for the slush skin before foaming, and foam carriers and tools are also onsite.

Additional capabilities in Chongqing include injection molding, seamless airbag scoring, foaming, roll-coating, lamination, various welding techniques, punch trimming, vacuum forming and cut and sew. The facility is also equipped with a full test lab capable of airbag deployment validation testing, material and environmental testing and precision Coordinate Measuring Machine (CMM) data collection.

Source: www.plasticstoday.com/articles/us-tier-i-opens-chongqing-auto-skin-facility-instrument%20panel-interior-20130422a