Avery Dennison, a pressure-sensitive label material manufacturer based in the US, announced on September 28 that it has, in collaboration

Avery Dennison, a pressure-sensitive label material manufacturer based in the US, announced on September 28 that it has, in collaboration

with printing solutions supplier Gallus Group, developed a new die-cutting technology ThinStream, which allows the die-cutting of labels with a liner as thin as 12 microns.

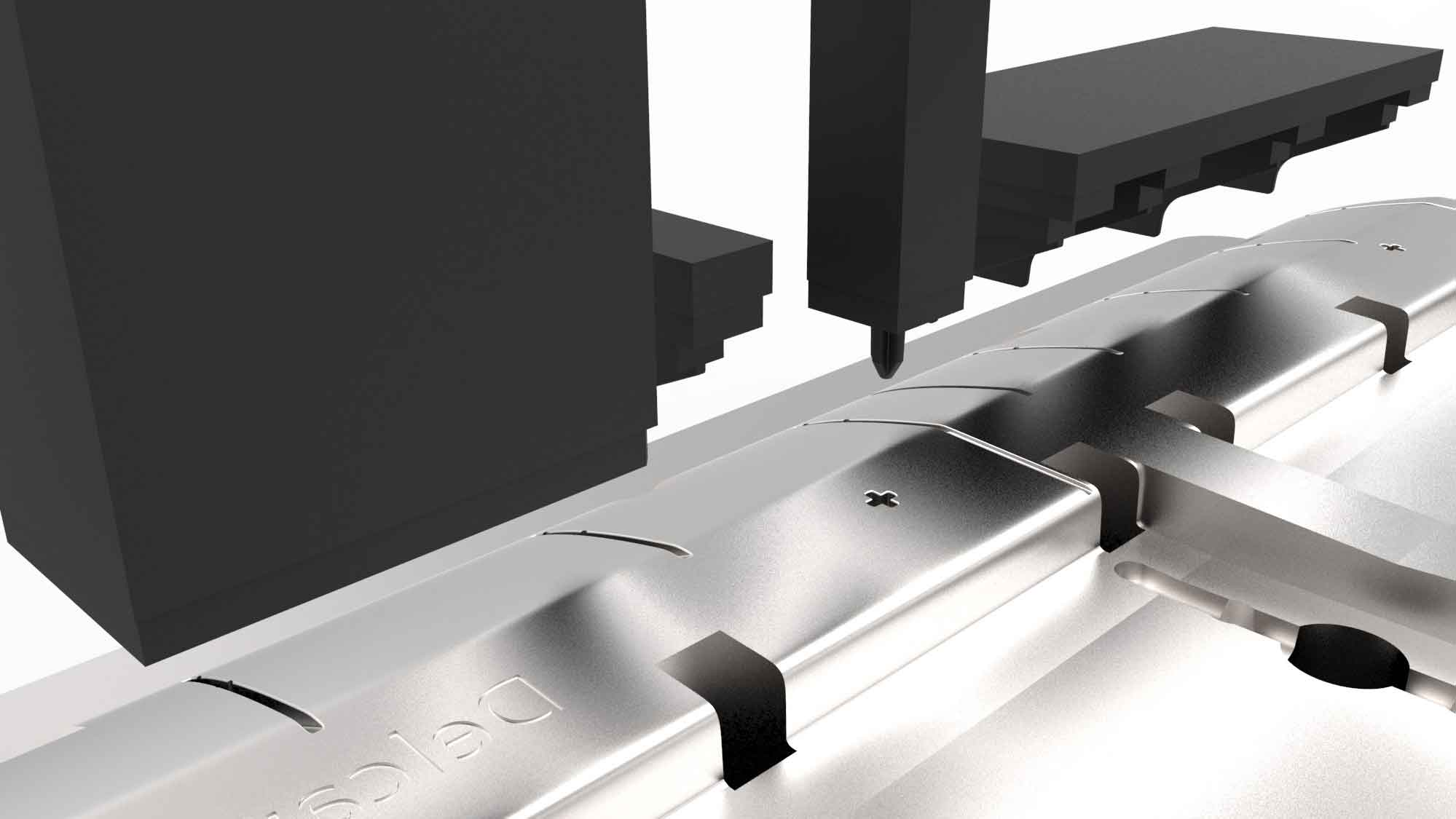

The ThinStream technology separates the face stock from the liner before die-cutting, cuts the label shape through the adhesive and then reassembles the label. In order to make a “clean cut”, the machine uses a cold die unit created by the Gallus Group, which is kept below freezing to prevent the adhesive from sticking to the die.

As said, thickness of the liner can be half of the current minimum in the market. The technology also avoids die strikes, and has been licensed to Gallus.

With conventional kiss-cutting, the die can cut through the liner and cause operation and quality problems during converting and dispensing. Die-cutting liner with calipers below 23 microns was not possible.

“Creating real breakthrough products by engaging with label converters, machine manufacturers, designers, brand owners and raw materials suppliers is the core of this strategy,” said Don Nolan, Group Vice President, Label and Packaging Materials.

ThinStream technology and the Gallus Cold Die Unit are suitable for label printers with large volume print jobs on PET liner, as stated. It can be integrated into a Gallus printing press or operate in a stand-alone version.

Avery Dennison and Gallus have been in cooperation since the 1940s.

Source : www.adsalecprj.com/