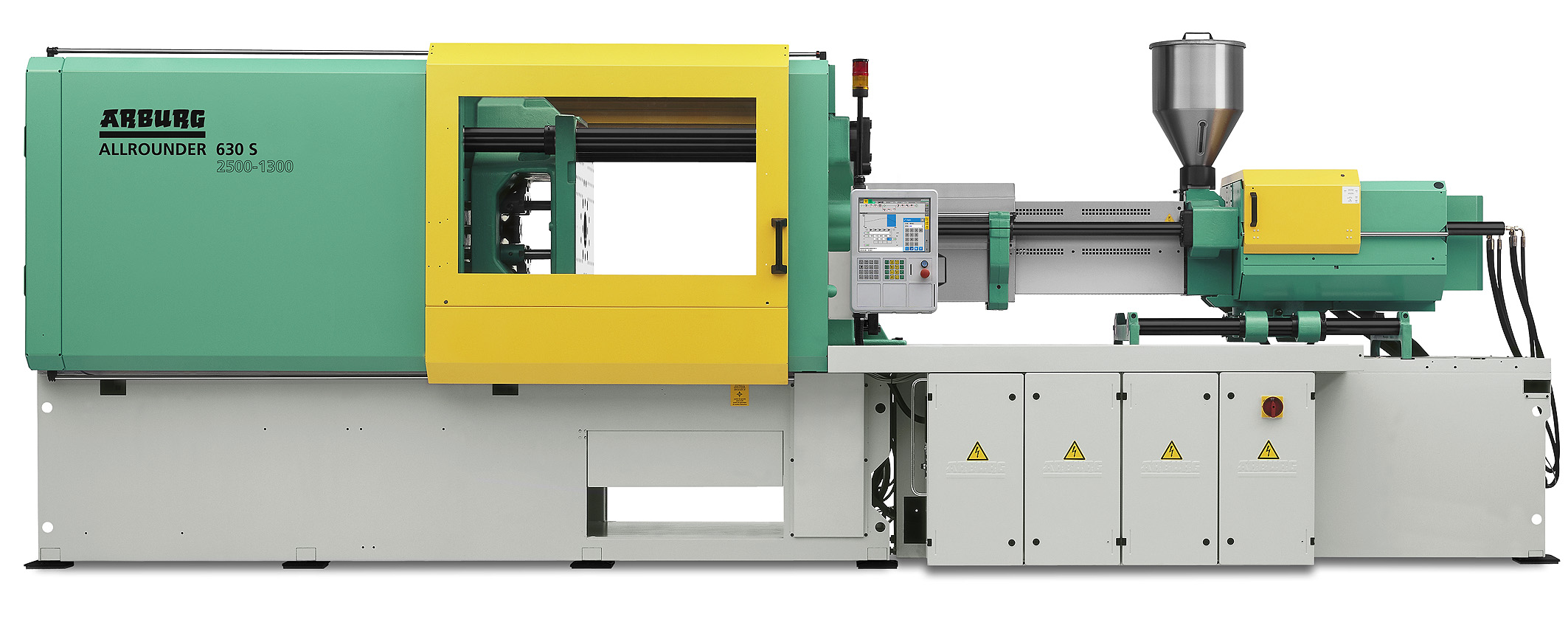

Jeff Somple, president of Mack Molding, and Bryan Campbell, plant manager, explain the use of one of the company’s

plastic molding machines at the Arlington plant on Tuesday. Mack has had a successful year with sales and staff increasing depite the weak economy.

While many manufacturers in Vermont and around the world are still feeling the effects of the recession, Mack Molding had an increase in sales during the last fiscal year of about 10 percent, added about 55 jobs in the last 18 months, and expects to add jobs and grow sales in the next year.

Jeff Somple, president of Mack Molding’s northern division, said the company, which describes itself as a “custom plastics molder” specializing in plastics design, large part molding and medical device manufacturing, was adding a machining center to its plant on Warm Brook Road in Arlington. The additional capacity is expected to employ another 10 to 15 people in a workforce of about 450.

According to Somple, Mack has been doing well because of a strategy developed around 10 years ago.

“When we first really tried to reinvent our business back in 2000, 2001, and when we recognized that a lot of the work that we were doing at that time, which was a lot of computer (parts) work, was going to be going off-shore, we did some really difficult meetings here. We tried to redefine what we were going to (be and asked) are we even going to exist. We really looked at some markets that we thought were going to be somewhat resistant to the trend to go to China and other off-shore companies. Medical popped right up at us,” he said.

Somple said the medical market has proven to be successful for Mack because companies making medical equipment wanted better quality control than they might be able to get internationally and needed to work closely with a company as they designed the product. That would be difficult when the manufacturer and the buyer were a 22-hour plane trip apart, he said.

Another market Mack pursued were pieces that Somple said were big and cost a lot to shop. On Tuesday, for instance, Mack’s factory workers were assembling and shipping a large device for Pitney-Bowes that mail marketers would use to sort mail.

Mack also went after accounts where the seller needed various colors and styles, like office furniture, and other items that would be manufactured in “small” batches.

“In our world, 10,000 is considered low volume. Things that aren’t millions but thousands… we really started looking for products like that,” Somple said.

Once Mack started getting the contracts to make products like medical devices and a milkshake machine that’s placed in a number of national convenience stores, word-of-mouth began to bring other customers to Mack.

Somple said Mack was also well-positioned to take advantage of opportunities that came because of the recession.

“Almost every one of our customers is another U.S. manufacturer. We make some or all of a product for them so they were really looking for people that were going to be around for the long haul, that had the money to invest in the technology and the people and the machinery required to make their product,” he said.

While Somple said he knew some in the manufacturing community were just happy not to lose ground, Mack has actually been increasing sales.

“We’ve aggressively pursued growth. We didn’t just hunker down and wait for the recession to pass,” said Julie Horst, a spokeswoman for Mack.

Somple used the example of Mack expanding to machining its own parts to keep quality control in-house and reduce wait time for parts. The Mack site in East Arlington is about to add the second-largest molding press, a 1,650-ton piece of equipment, in January.

The largest press is in Mack’s third manufacturing plant in Vermont in Cavendish. Throughout the company, Mack has about 125 molding presses.

Mack hasn’t just added equipment. From April 2009 to now, about 50 to 55 new employees have been taken on “during a fragile economic recovery,” Horst pointed out.

Some Mack employees are third-generation employees of the company which was founded in 1920. Mack was co-founded by the Kendall family in Vermont and Don Kendall still lives in Arlington. The Kendall family bought out its partners 50 years ago.

Source : www.rutlandherald.com