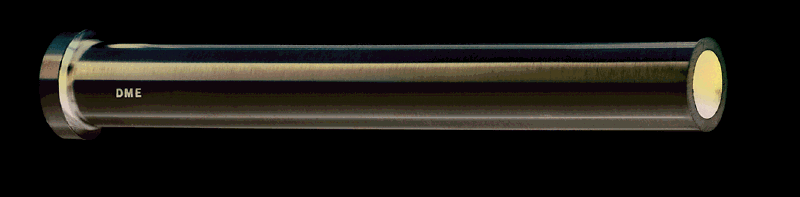

DME Company, a leading manufacturer of mold technologies, recently expanded its line of SND-style Sleeves. The addition of the new lengths rounds out the company’s SND offering, providing a large breadth of product to meet mold designers’ requirements. “We’ve once again responded to requests from our customers,” said John Harding, DME Manager, Global Sourcing. “We’ve provided more options for ejector sleeves they can depend on, shot after shot.”

DME Ejector Sleeves are made of thermal-shock resisting hotwork die steel. This high-strength steel has the physical properties to withstand the continuous punishment – the friction, the thermal and mechanical stresses – of plastics molding and die casting. DME has developed its own technology and sophisticated equipment for hot-forging. Totally automatic, this equipment controls temperatures closely within 9°F (5°C), a major factor in producing uniform grain flow in DME Ejector Sleeves, increasing their density and tensile strength.

To create the strongest bond between the hard surface case and tough core, DME also uses a highly advanced nitriding process. “We use automated equipment to closely and continually monitor and control temperatures, processing time and the ammonia atmosphere,” said Harding. “This is the only way to produce sleeves and ejector pins with high surface hardness and good, tough cores.” SND-style sleeves are now available with 0.375- to 1.25- inch head diameters and 3- to 14- inch lengths.

Features

- 142 size combinations available

- Hot forged heads for uniform grain flow and higher tensile strength

- Nitrided Outer Diameter (O.D.) and Inner Diameter (I.D.) for longer wear resistance

- Nitrided inside bearing diameter

· Centerless ground and polished outer diameter

· Precision made of superior quality thermal shock resisting hotwork die steel

Benefits

- Hot-forged heads provide uniform grain flow, higher tensile strength

- Lead-in taper designed allows interference-free entry of the ejector pin into the sleeve

- Longer wear resistance and improved lubricity

- Smoother movement enabled by inside bearing diameter nitrided to 65-74 HRC hardness with a honed finish

- Minimized wear through outside diameter nitrided to 65-74 HRC hardness and finished

DME also recently expanded its line of EXK Keyed Ejector Pins, giving customers more options than ever for mold ejection.

More Information : www.dme.net