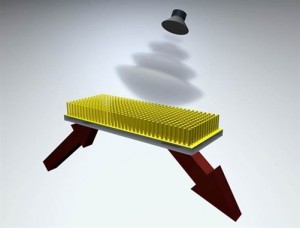

A polypyrolle compound developed by an international research team converts ultrasound waves into optical signals that can be used to produce an image. In the research study, polypyrolle, a conductive plastic, was compounded with gold nanorods, which generally are available in diameters from 10-50 nm. An optical signal transmitted into the plastics compound interacts with inbound ultrasound waves and then passes through. A specialized transducer reads the signal and converts it into an image.

“A high bandwidth allows you to sample the change of distance of the acoustic waves with a high precision,” says Vladislav Yakovlev, a professor at Texas A&M University. “This translates into an image that shows greater detail. Greater sensitivity enables you to see deeper in tissue, suggesting we have the potential to generate images that might have previously not been possible with conventional ultrasound technology.”

The research was a collaboration between Texas A&M University’s Department of Biomedical Engineering, The Queen’s University of Belfast, and the University of Massachusetts Lowell. Their findings are published in the current issue of Advanced Materials.

In conventional ultrasound technology, images are generated by converting ultrasound waves into electrical signals and is constrained by bandwidth and sensitivity limitations, according to Yakovlev. As a result, high-quality images have not been available. Ultrasound is well known as looking at fetuses and is also used for diagnostic purposes in trauma inncidents and even as a means of breaking up tissue and accelerating the effects of drugs therapies.

At this point, the research is just a demonstration, and is not yet ready to be integrated into medical imaging programs. “We developed a material that would enable optical signal processing of ultrasound,” Yakovlev says. “Nothing like this material exists in nature so we engineered a material that would provide the properties we needed. It has greater sensitivity and broader bandwidth. We can go from 0-150 MHz without sacrificing the sensitivity. Current technology typically experiences a substantial decline in sensitivity around 50 MHz.”

Source: http://www.plasticstoday.com/articles/new-compound-raises-bar-medical-plastics0308201301