Kobusch UK, a member of Sun Capital Partners, Inc, is set to conclude its planned expansion in the field of recycled PET (rPET) early in 2013 with the installation of a new inline sheet facility from EREMA and SML at its Stanley, the UK plant.

The system will enable Kobusch UK to produce 100% food-contact compliant rPET flat sheet.Tony Mitchell, Kobusch UK Sales Director explains, “With this 3 million euro investment Sun Capital has demonstrated its support for our plans for growth. We intend to keep the existing extrusion division in Stanley in operation for our expansion plans. The new EREMA system with SML downstream equipment will enable us to continue to increase the amount of post-consumer waste in our rPET production without sacrificing any quality in clarity in the thermoforming process.”

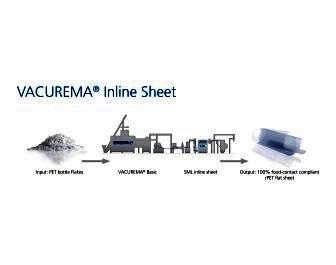

The company is already running a VACUREMA Basic 1514 T from EREMA with a directly connected downstream flat sheet system from SML to process post-consumer PET bottle flakes and Kobusch’s own production waste to produce food-contact approved rPET sheet for the production of thermoformed PET trays. The new, larger system will go on stream in the first half of 2013, enabling a total throughput of up to 1,400kg/h.

“Thanks to the efficient decontamination of the flakes, Kobusch UK is even able to use the VACUREMA to produce food-contact grade sheet purely from rPET,” says Manfred Hackl, joint CEO at EREMA, outlining a further benefit of the system. Another unique benefit is the increased value added as a result of the direct production of the flat sheet without the intermediate stage of pelletizing.

Source: http://www.adsalecprj.com/Publicity/MarketNews/lang-eng/article-67003099/Article.aspx