Kettering University is collaborating with Intech Energy Storage Corporation (IESC) of Toronto, Canada, to test the critical characteristics of, and experimentally fabricate, a newly designed aluminum-based battery that is more versatile, has a longer shelf life and is made of environmentally friendly, non-toxic, low cost components.

Dr. Matthew Sanders, professor of Industrial and Manufacturing Engineering and director of the Center of Culminating Undergraduate Experiences (CUE) at Kettering, has received a funded research grant from IESC to perform validation testing on the batteries in an on-campus, multidisciplinary project. He will collaborate with Dr. Alexandre Iarochenko, president of Intech Energy Storage Corporation, on the research.

The aluminum battery validation project is the pilot for the multidisciplinary CUE. It will involve students and faculty from the Electrical and Computer Engineering, Chemistry, Mechanical Engineering and Industrial and Manufacturing Engineering departments.

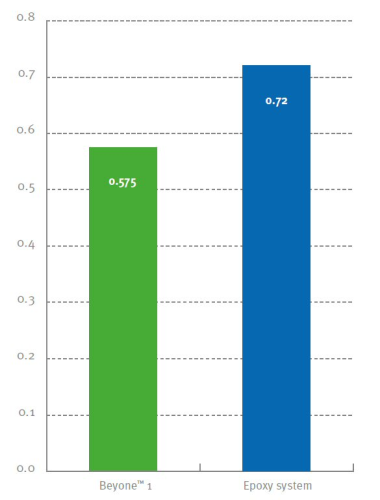

IESC believes that the aluminum-based battery they have developed may achieve energy densities in excess of those of existing batteries, and that they have overcome the problems identified with existing aluminum batteries such as hydrogen corrosion, early dry out, high cost, low shelf life, positional restrictions and start-up time, according to Sanders.

“It is our responsibility to examine the battery design and determine if IESC’s claims are accurate,” said Sanders. “In essence, we need to determine how fast the battery uncharges. There is currently a lot of ambiguity, so we will need to identify any problems that need to be resolved prior to taking the product to market,” he explained.

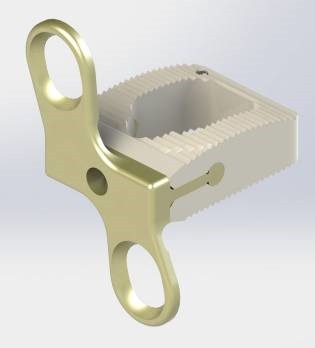

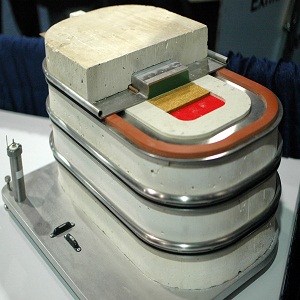

The battery is made of aluminum and organic materials. “There are no harmful metals involved,” said Sanders, “it is a green battery.” Sanders described the battery design as layers of aluminum and other non-harmful metals and layers of a proprietary organic material. The more layers the stronger the battery, he said.

According to IESC, the battery concept can be used in every type of battery from a pacemaker to a truck or boat motor. The possible intended uses for the battery include land and sea transportation vehicles, multi-purpose usage such as laptops and cell phones as well as specialty products such as military equipment.

“We will apply standard research protocols and methodologies to examine the battery under different conditions to determine its durability,” said Sanders. Phase 1 of the project is estimated to take up to 12 months to complete, and includes building a prototype for testing. In the first set of tests, Kettering’s IME Department will assess the battery’s performance when exposed to extreme heat and cold.